1. Introduction

In the complex and ever-evolving landscape of manufacturing, one size does not fit all. Especially for businesses engaged in Engineer-to-Order (ETO) manufacturing, where each project is unique and tailored to meet the specific needs of clients, a one-size-fits-all approach simply won't cut it. This is where the role of an ETO ERP (Enterprise Resource Planning) software system becomes paramount.

The selection of the right ETO ERP software can be a game-changer for businesses operating in the ETO space. It's not just about choosing any ERP system; it's about choosing the one that aligns seamlessly with your unique business processes and objectives. In this article, we will explore the crucial considerations that can make all the difference when it comes to selecting the ideal ETO ERP solution.

Defining ETO ERP Software

Before we dive into the specifics, let's clarify what ETO ERP software is and why it's so essential for businesses in the ETO manufacturing sector.

Engineer-to-Order (ETO) manufacturing is a mode of production where each product is designed and built to meet the precise specifications of individual customers. Unlike traditional manufacturing, where products are mass-produced based on forecasts, ETO manufacturing is all about customization. It's about crafting one-of-a-kind solutions that satisfy the unique demands of clients in industries like construction, aerospace, and industrial machinery.

Now, imagine managing the intricacies of ETO manufacturing without a robust system in place. The chaos that could ensue from manually tracking orders, materials, labor, and project timelines is enough to give any business owner nightmares. This is where ETO ERP software comes into play.

ETO ERP software is a specialized category of ERP systems tailored to meet the distinctive needs of ETO manufacturers. It's a comprehensive solution that integrates and streamlines all aspects of your business, from project management and engineering to procurement and financials. With ETO ERP, you can bid farewell to spreadsheets, manual data entry, and fragmented information systems.

The Importance of Choosing the Right Solution

Selecting the right ETO ERP software is a decision that can profoundly impact your business's efficiency, competitiveness, and profitability. Conversely, choosing the wrong solution can lead to costly errors, delays, and frustration.

Consider this: ETO manufacturing projects are often high-stakes endeavors with tight deadlines and intricate requirements. The right ETO ERP software can empower your team to meet these challenges head-on. It can provide real-time visibility into project progress, help you manage resources effectively, and ensure that your projects are delivered on time and within budget.

On the flip side, a poorly chosen ETO ERP system can become a hindrance rather than a help. It can lead to data inaccuracies, process bottlenecks, and a host of operational headaches. Moreover, the cost of implementing and maintaining an ERP system is not trivial, so making the wrong choice can be an expensive mistake.

In the sections that follow, we'll delve deeper into the key considerations you should keep in mind when selecting ETO ERP software. From industry-specific features to scalability, integration capabilities, and ongoing support, we'll guide you through the decision-making process to ensure you make the right choice for your ETO manufacturing business.

So, if you're ready to embark on the journey of selecting the perfect ETO ERP solution for your business, let's begin by understanding the unique nature of engineer-to-order manufacturing and why ETO ERP software is the linchpin that can help you thrive in this dynamic industry.

Stay with us as we explore the intricacies of ETO ERP software and equip you with the knowledge you need to make an informed decision that will benefit your business for years to come. In the next section, we'll delve deeper into the world of Engineer-to-Order manufacturing, highlighting what sets it apart from other manufacturing methods and why it necessitates a specialized ERP solution.

2. Understanding Engineer-to-Order Manufacturing

Engineer-to-Order (ETO) manufacturing is a unique and highly flexible approach to production. Unlike traditional manufacturing, where products are standardized and produced in large quantities, ETO manufacturing revolves around creating custom, one-of-a-kind products. Each project in ETO manufacturing is essentially a new venture, and it requires a level of adaptability and precision that sets it apart from other manufacturing methods.

What Sets ETO Manufacturing Apart

In ETO manufacturing, the production process begins with the customer's order. This order could be for a complex piece of machinery, a customized building, or any other product designed to meet specific client requirements. Here are some key characteristics that differentiate ETO manufacturing from other approaches:

- High Customization: ETO products are tailored to meet the unique needs and specifications of individual customers. This often involves extensive engineering and design work to ensure that the final product aligns perfectly with the client's requirements.

- Project-Based: ETO manufacturing projects are typically organized as individual projects, each with its own set of tasks, timelines, and resource requirements. This project-based nature adds complexity to project management and tracking.

- Varied Components: ETO products may involve a wide range of components and materials, some of which may be standard, while others are custom-made. Coordinating the procurement and assembly of these components can be challenging.

- Resource Intensive: The process often requires a significant amount of resources, including skilled labor, specialized equipment, and materials. Efficiently managing these resources is essential for profitability.

- Engineering Expertise: Due to the need for customization, engineering and design play a central role in ETO manufacturing. Projects often involve complex calculations, CAD (Computer-Aided Design) work, and collaboration between engineers and production teams.

Given the unique nature of ETO manufacturing, it's easy to see why a standard ERP system might not suffice. ETO businesses need an ERP solution that can adapt to the variability, project-based nature, and customization requirements inherent to their operations.

The Role of ERP in ETO Businesses

This is where ETO ERP software comes into play. It's designed specifically to address the intricacies of ETO manufacturing, providing a unified platform to manage and streamline operations. Here's how ETO ERP software can benefit businesses in this sector:

- Project Management: ETO ERP systems offer robust project management tools that allow businesses to create, track, and manage projects efficiently. This includes assigning tasks, setting timelines, and monitoring resource allocation.

- Engineering Integration: ETO ERP software often integrates with engineering and CAD systems, ensuring that design changes and engineering calculations are seamlessly incorporated into the production process.

- Customization Support: These systems enable businesses to configure their workflows and processes to align with the unique requirements of each project. This level of customization is critical in ETO manufacturing.

- Cost Control: ETO ERP software helps monitor project costs in real-time, allowing businesses to stay within budget and make informed decisions to maximize profitability.

- Resource Optimization: Efficient allocation of labor, equipment, and materials is essential in ETO manufacturing. ETO ERP systems provide visibility into resource availability and help optimize their use.

In summary, ETO ERP software is the linchpin that enables businesses engaged in engineer-to-order manufacturing to thrive in an environment characterized by complexity, customization, and variability. With its project management capabilities, engineering integration, and customization support, ETO ERP software empowers businesses to tackle the unique challenges they face and deliver high-quality, customized products on time and within budget.

In the next section of this article, we'll dive into the critical considerations you should keep in mind when selecting the right ETO ERP software for your business. Understanding the specific needs of your ETO manufacturing operation is the first step toward making an informed choice.

3. The Impact of Choosing the Wrong ERP Software

Before we delve into the key considerations for selecting the right ETO ERP software, it's important to understand the potential consequences of choosing the wrong one. Implementing an ERP system that isn't well-suited to your ETO manufacturing business can lead to a cascade of challenges and setbacks.

Common Pitfalls and Consequences

- Inefficiency: An ill-fitting ERP system can disrupt your workflow and lead to inefficiencies. This might result from manual workarounds to accommodate your unique processes or a lack of integration with critical systems.

- Cost Overruns: ETO projects often have tight budgets. Choosing an ERP system that doesn't provide precise cost tracking and control can lead to cost overruns that erode your profitability.

- Missed Deadlines: In ETO manufacturing, delivering projects on time is crucial to customer satisfaction. An inadequate ERP system may hinder your ability to manage project timelines effectively.

- Quality Issues: Customized products require rigorous quality control. If your ERP system doesn't support comprehensive quality management, it could result in quality issues and customer dissatisfaction.

- Data Inaccuracy: Inaccurate data can lead to poor decision-making. An ERP system that fails to maintain data accuracy can have far-reaching consequences throughout your organization.

- Lost Opportunities: The wrong ERP system may lack the flexibility to adapt to changing customer demands or market trends, potentially causing you to miss out on new opportunities.

- Employee Frustration: Complex, user-unfriendly ERP systems can frustrate your employees, leading to decreased morale and decreased productivity.

- Long-Term Costs: The cost of ERP implementation extends beyond the initial investment. Ongoing support, maintenance, and potential upgrades can become more expensive if your ERP system isn't the right fit.

- Competitive Disadvantage: In the highly competitive ETO manufacturing sector, having the wrong ERP system can put you at a disadvantage compared to competitors who have chosen more suitable solutions.

Clearly, the consequences of choosing the wrong ETO ERP software extend beyond financial losses. They can impact your reputation, customer relationships, and the overall sustainability of your business.

In the sections that follow, we'll explore the critical considerations that will help you avoid these pitfalls and select an ETO ERP system that aligns perfectly with your business needs. By taking a systematic approach to your decision-making process, you can ensure that the ERP software you choose empowers your business to excel in the world of Engineer-to-Order manufacturing.

Now that we've discussed the potential repercussions of a poor ERP choice, let's dive into the key considerations you should keep in mind when evaluating ETO ERP software options in the next section.

4. Key Considerations for Selecting ETO ERP Software

Selecting the right ETO ERP software is a decision that should be approached with careful consideration and a thorough understanding of your business's unique needs. In this section, we'll explore the crucial factors you should take into account when evaluating ETO ERP software options.

4.1. Industry-Specific Features

ETO manufacturing operates in a niche within the broader manufacturing landscape. It's essential to choose an ETO ERP system that offers industry-specific features and functionalities tailored to your needs. These features may include:

- Project Management: Robust project management tools that enable you to create, track, and manage ETO projects efficiently.

- Engineering Integration: Integration with engineering software and CAD systems to ensure seamless communication between design and production.

- Customization Support: The ability to configure the ERP system to align with your unique project workflows, processes, and requirements.

- BOM (Bill of Materials) Management: Comprehensive management of bills of materials, which are often complex and variable in ETO manufacturing.

- Resource Scheduling: Tools for effective scheduling of labor, equipment, and materials, which is crucial in a project-based environment.

- Quality Control: Features for quality management, including inspections, testing, and compliance tracking.

4.2. Scalability and Customization

ETO businesses can experience significant fluctuations in project volume. Your chosen ERP system should be scalable to accommodate growth and adaptable to handle fluctuations in project size and complexity. Scalability ensures that your ERP investment remains viable as your business expands.

Customization capabilities are equally important. ETO manufacturing thrives on the ability to tailor products to precise customer specifications, and your ERP system should support this level of customization. It should allow you to configure workflows, reports, and data fields to match your unique processes.

4.3. Integration Capabilities

An effective ETO ERP system should seamlessly integrate with other critical software solutions you use, such as CAD software, procurement systems, and financial management tools. Integration ensures data consistency across your organization and streamlines processes.

Consider whether the ERP system can integrate with your existing software stack or if it requires additional customization. A well-integrated ecosystem can significantly improve efficiency and data accuracy.

4.4. User-Friendliness and Training

The usability of your chosen ERP system is vital. It should be intuitive and user-friendly to minimize training time and reduce the risk of errors during implementation. Look for software providers that offer comprehensive training and support programs to ensure your team can effectively use the system.

Evaluate the availability of user resources such as documentation, video tutorials, and user communities. These resources can be invaluable for ongoing learning and troubleshooting.

4.5. Vendor Reputation and Support

Research the reputation and track record of the ERP software vendor. Consider factors such as the vendor's experience in serving ETO manufacturing businesses, customer reviews, and case studies. A vendor with a strong industry presence is more likely to understand and address your specific needs.

Additionally, inquire about the vendor's support services. Effective post-implementation support is crucial for resolving issues, staying up-to-date with software updates, and ensuring the long-term success of your ERP system.

In the next section, we'll guide you through the process of assessing your ETO ERP needs by evaluating your business requirements and creating a checklist to aid in your decision-making process.

5. Assessing Your ETO ERP Needs

Before diving into the sea of ETO ERP software options, it's crucial to assess your business's specific requirements and priorities. This step is essential for understanding the exact functionalities and features you need in an ERP system. Here's how you can go about it:

Evaluating Your Business Requirements

- Project Complexity: Consider the typical complexity of your ETO projects. Are they relatively straightforward, or do they involve intricate engineering and customization? The level of project complexity will influence the required features in your ERP system.

- Resource Management: How do you currently manage resources, including labor, materials, and equipment? Assess your resource management processes to identify areas that could benefit from automation or improvement through an ERP system.

- Integration Needs: List the software tools and systems your business relies on, such as CAD software, procurement systems, or financial management platforms. Identify which of these systems should integrate with your ETO ERP software.

- Data and Reporting: Determine the specific data points and reporting capabilities critical to your business. Consider what insights you need to track project costs, monitor progress, and make informed decisions.

- Growth Plans: Think about your business's growth trajectory. Do you anticipate an increase in the number or complexity of ETO projects? Ensure that the ERP system you choose can scale with your business.

- Budget Constraints: Assess your budget for ERP implementation, including both upfront costs and ongoing expenses. Be realistic about your financial constraints while also considering the long-term ROI of the ERP investment.

Creating a Checklist

To simplify the decision-making process and ensure you don't overlook any critical factors, create a checklist based on your business requirements. This checklist can serve as a reference when evaluating potential ETO ERP software solutions. Here's a sample checklist:

- Project Management: Does the ERP system offer robust project management tools tailored to ETO projects?

- Engineering Integration: Does the ERP system seamlessly integrate with engineering and CAD software?

- Customization: Can the ERP system be configured to match our unique workflows and processes?

- Scalability: Is the ERP system scalable to accommodate future growth and fluctuations in project volume?

- Integration: Does the ERP system integrate with our existing software solutions, such as procurement and financial systems?

- User-Friendliness: Is the ERP system user-friendly, and does it provide adequate training and support?

- Vendor Reputation: Has the ERP software vendor demonstrated a strong track record of serving ETO manufacturing businesses?

- Support Services: What level of post-implementation support and maintenance does the vendor offer?

By systematically evaluating your business requirements and creating a checklist, you can approach the selection process with a clear understanding of your needs and priorities. This will help you identify the ETO ERP software that aligns most closely with your specific business goals.

In the following section, we'll explore the landscape of ETO ERP options, providing an overview of leading ETO ERP software providers and sharing real-world examples of successful implementations to offer insights into your decision-making process.

6. Exploring ETO ERP Options

Now that you have a clear understanding of your ETO ERP needs and priorities, it's time to explore the landscape of ETO ERP software options. In this section, we'll provide an overview of leading ETO ERP software providers and share real-world examples of objectives and results for an ETO ERP Software to offer insights into your decision-making process.

Overview of Leading ETO ERP Software Providers

When it comes to choosing ETO ERP software, you have several reputable options to consider. Here are a few of the leading ETO ERP software providers:

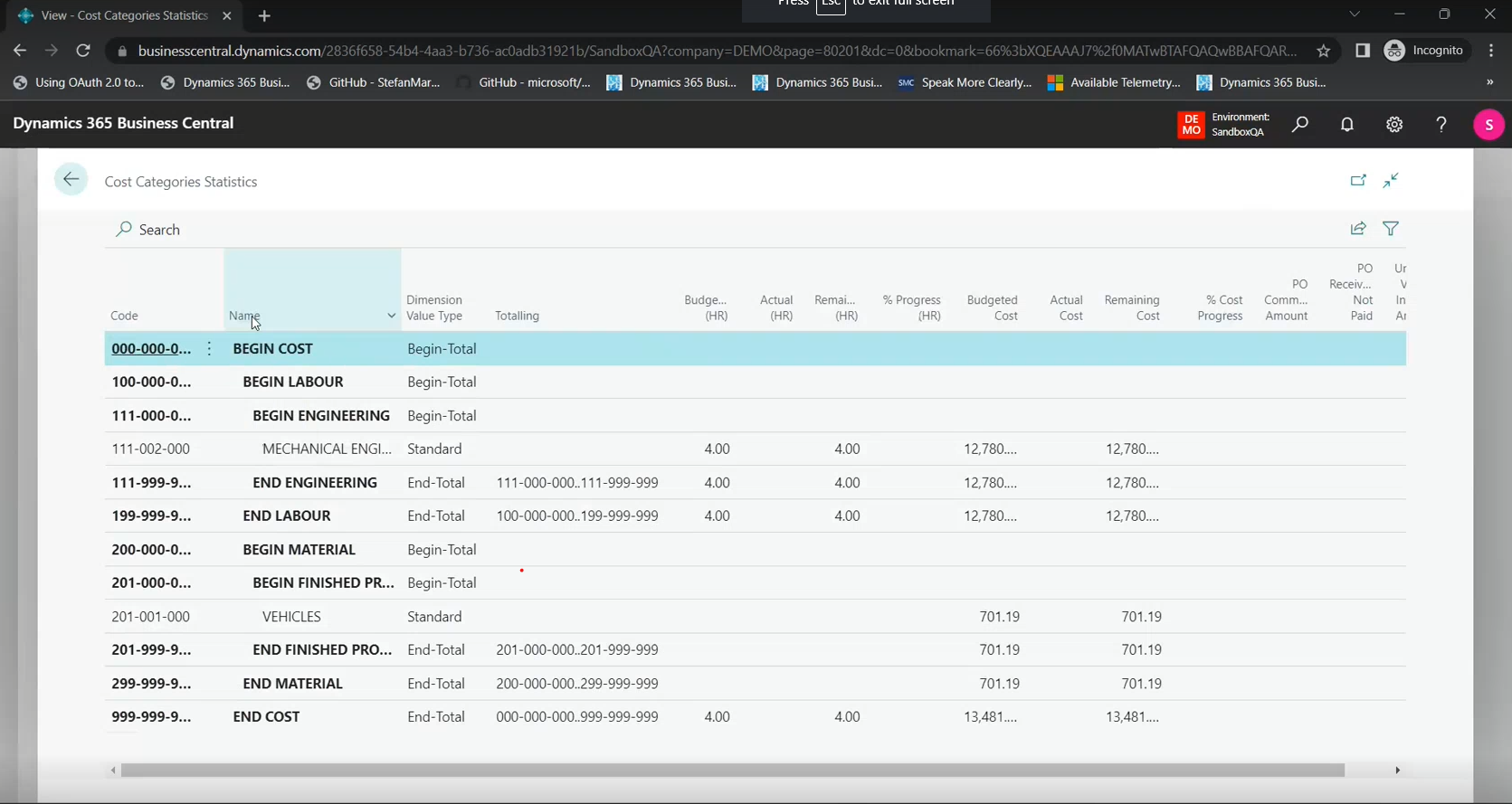

- Microsoft Dynamics 365 Business Central: Microsoft's Business Central offers a comprehensive ERP solution that can be customized for ETO manufacturing needs. It provides project management, resource optimization, and engineering integration.

- Epicor ERP: Epicor offers a specialized ETO module within its ERP system, catering to the unique needs of ETO manufacturers. It provides project management, engineering integration, and customization capabilities.

- IFS Applications: IFS Applications offers a comprehensive ERP solution that includes features tailored to ETO manufacturing. It emphasizes project management, resource optimization, and engineering integration.

- Infor CloudSuite Industrial (SyteLine): Infor's CloudSuite Industrial, formerly known as SyteLine, is designed for various manufacturing types, including ETO. It offers a robust suite of manufacturing and project management tools.

- Oracle NetSuite: NetSuite provides a cloud-based ERP solution that can be tailored to ETO manufacturing needs. It offers financials, project management, and scalability.

Let's explore an example of how an Engineer-to-Order (ETO) manufacturing company can effectively use an ETO ERP (Enterprise Resource Planning) system to streamline its operations and improve overall efficiency.

Company Profile: Example Custom Machinery

Example Custom Machinery is a medium-sized ETO manufacturing company that specializes in designing and fabricating customized industrial machinery. Their products are tailored to meet the unique needs of their clients in various industries, such as automotive, aerospace, and pharmaceuticals.

Challenges Faced by Example Custom Machinery

Before implementing an ETO ERP system, Example Custom Machinery encountered several challenges in their daily operations:

- Project Complexity: Each machinery project was highly complex, involving intricate design specifications and unique components. Managing these projects efficiently was a daunting task.

- Resource Allocation: Resource management, including skilled labor, materials, and equipment, was a constant challenge. Misallocation of resources often led to delays and increased costs.

- Project Tracking: Tracking project progress, costs, and timelines in real-time was nearly impossible due to manual processes and disparate systems.

- Engineering and Design Integration: Communication between the engineering and production teams was often fragmented, leading to design changes that weren't seamlessly integrated into production.

Implementing ETO ERP: A Game-Changer for Example Custom Machinery

Example Custom Machinery recognized the need for a specialized ETO ERP system to address these challenges. Here's how they effectively used their ETO ERP system to transform their operations:

1. Streamlined Project Management:

- Project Creation: With the ETO ERP system, Example Custom Machinery could quickly create projects for each custom machinery order. The system allowed them to define project tasks, timelines, and resource requirements.

- Resource Allocation: The ERP system provided a unified view of resource availability, making it easier to allocate labor, equipment, and materials efficiently. It helped prevent overallocation and delays.

2. Enhanced Engineering Integration:

- CAD Integration: The ETO ERP system seamlessly integrated with their Computer-Aided Design (CAD) software. This integration allowed design changes to flow directly into the production process, reducing errors and rework.

- Engineering Collaboration: Engineers and production teams could collaborate more effectively within the ERP system, ensuring that design changes were communicated and implemented without delays.

3. Real-Time Project Tracking:

- Cost Monitoring: The ERP system enabled real-time tracking of project costs. Example Custom Machinery could monitor expenditures on materials, labor, and other resources to ensure projects stayed within budget.

- Timeline Management: They could easily monitor project timelines, identifying potential bottlenecks or delays and taking corrective actions promptly.

4. Customization Support:

- Workflow Configuration: The ETO ERP system allowed Example Custom Machinery to configure workflows to match the specific requirements of each project. This customization ensured that no two projects were managed in exactly the same way.

- Bill of Materials (BOM) Management: Complex BOMs for custom machinery could be efficiently managed within the system, ensuring that all required components were procured and assembled correctly.

Results and Benefits:

The implementation of the ETO ERP system yielded significant benefits for Example Custom Machinery:

- Improved Efficiency: Project management became more efficient, leading to shorter lead times and reduced project costs.

- Enhanced Resource Utilization: Resource allocation and scheduling were optimized, reducing labor and material wastage.

- Increased Profitability: With better cost control and project tracking, Example Custom Machinery saw increased profitability on their projects.

- Customer Satisfaction: Meeting project timelines and delivering high-quality, customized machinery improved customer satisfaction and generated repeat business.

In summary, Example Custom Machinery's successful use of an ETO ERP system transformed their ETO manufacturing operations. By streamlining project management, enhancing engineering integration, enabling real-time tracking, and providing customization support, they achieved greater efficiency, profitability, and customer satisfaction.

This example illustrates how an ETO ERP system can be a game-changer for ETO manufacturing companies, allowing them to thrive in a complex and highly customized production environment.

In the next section of this article, we'll delve into the critical consideration of cost when selecting ETO ERP software. We'll explore licensing models, hidden costs, and how to budget effectively for your ERP implementation.

7. Cost Considerations

Choosing the right ETO ERP software involves not only evaluating features and functionality but also carefully considering the costs associated with implementation and ongoing usage. In this section, we'll explore various cost considerations to help you make an informed decision.

Licensing and Subscription Models

ETO ERP software is available through different licensing and pricing models. Here are some common approaches:

- Per-User Licensing:

Liked what you just read? Sharing is caring.

October 13, 2023 by Frédéric Charest by Frédéric Charest VP of Marketing

Data-driven Growth Marketer with a Passion for SEO - Driving Results through Analytics and Optimization